Vibrating Feeding Bunker

Feeding

Bunker

Vibro

Motor

Feeding

Bunker

Folding Type

Bunker Covers

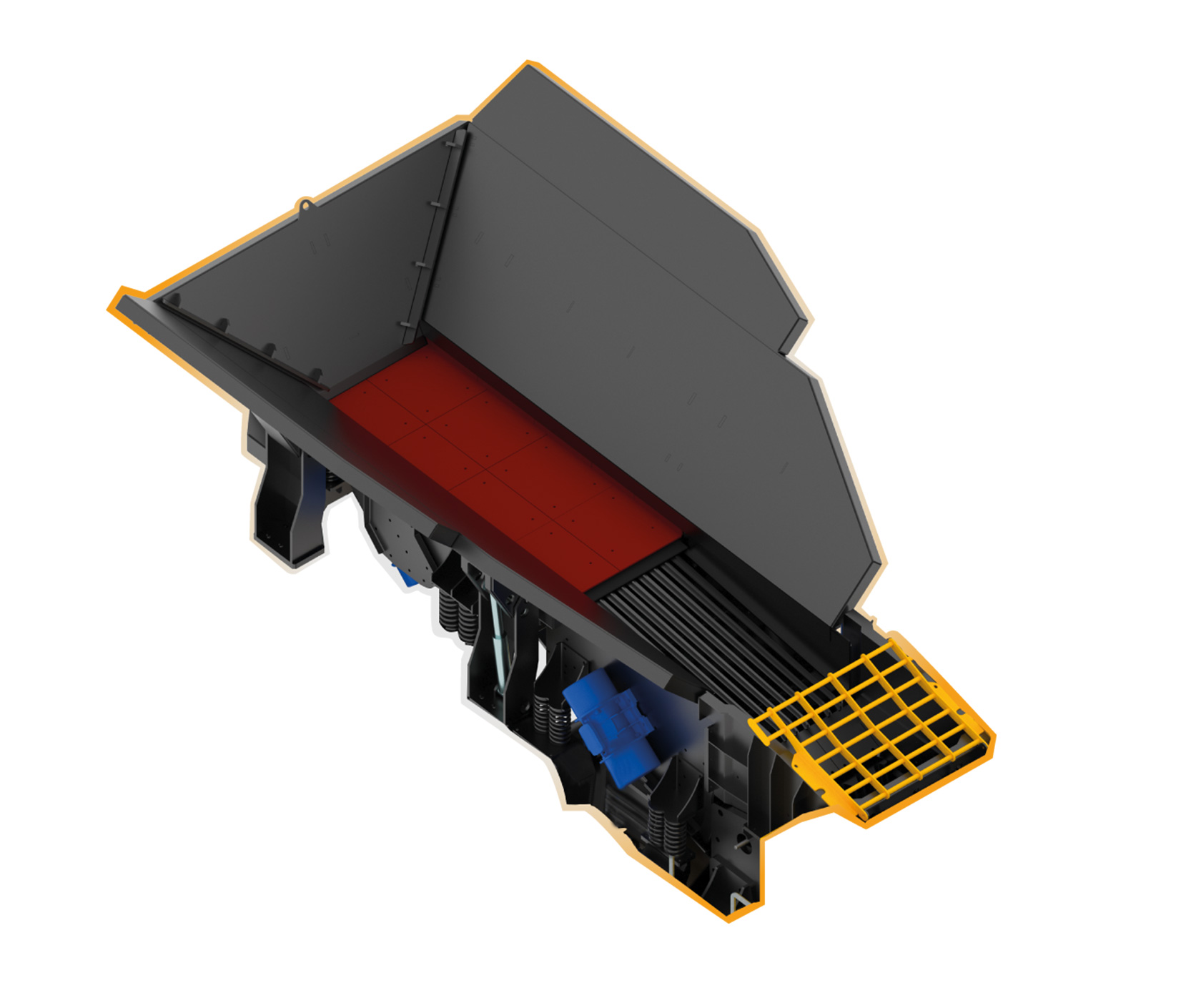

The Vibrating Feeding Bunker is a system that gains vibration capability with vibro motors and steel springs, sending the products loaded into the bunker quickly towards the crusher with its vibrating structure.

Thanks to its durable body structure and A1 Quality steel springs, which are the biggest factor in vibration, it has a long service life.

Grizzly screen technology is used to prevent muddy products from being sent into the crusher. The grizzly screen’s grid system is produced with bolted type. This reduces the assembly-disassembly time of the grids.

The screening sizes of the grizzly screen are determined according to the user’s request.

The grizzly screen gains vibration capability with vibro motors and steel springs.

Turbo Impact Crusher

Impact

Crusher

Durable

Pendulum System

Dayanıklı

Rotor ve Paletler

Hydraulic

Body

Turbo Impact Crusher is designed to crush soft and medium hard stones.

The plant breaks the products by hitting the pendulum with the pallets on the rotor rotating at high speed. Thanks to the hydraulically adjustable pendulum opening, it enables the products to be obtained in the desired size.

The inner body of the crusher is protected by linings. Linings prevent wear of the turbo impact crusher body and offer a long service life. The protection linings, which are fixed to the breaker body with bolts, can be easily changed by a personnel.

Stock Belts

Folding Type

Conveyor Belt

Belt

Traverses

Drive

Drums

Coupled

Motors

FABO folding type stock conveyor belts are equipments that quickly send crushed products to the stock area.

With its foldable structure, conveyor belts minimizes the dimensions of the machine it is on.

The band tires, which are produced resistant to wear, will never let you down and offer many years of service life.

Separator Belt

Separator

Belt

3-Pole

Magnetic Field

Drive

Drums

Coupled

Motors

The oversized conveyor belt metal separators consist of the main magnetic block, an endless separator belt, its motor, and the magnetic isolated steel frame as the main components. The steel frame of the MBS series magnetic separators, which are permanent magnet, is magnetically isolated and does not allow unwanted metal to stick around it.

Track System

Track

System

Versatile

Mobility

Double-Stage

Speed Adjustment

500 mm

Track Width

The fundamental element that allows the machine to move is the track system. The tracks, which have a thickness of 500 mm, have versatile mobility capabilities.

They are resistant to challenging terrain conditions. FABO does not neglect the importance of the track system in the crushing plant, carries out various R&D studies to provide its users with maximum compliance with A1 Quality and CE standards.

Automation System

Professional

Interface

PLC

Remote

Control

Heat Sensor

Protection (Opitional)

The tracked crushing plant is controlled by a full automation system. The machine’s operating mode is adjusted through the automation system panel located on the machine.

Equipment that forms the basis of the machine, such as the crusher, stock conveyors, and feed hoppers, is controlled by the automation system.

The automation system that allows you to use the tracked crushing plant in the most efficient way is prepared with PLC and serves its users with the most advanced form of technology.

Generator

Generator

Low

Fuel Consumption

High

Efficiency

Hybrid

Technology

The generator is the system that provides the power required for the operation of the machine without interruption. The generator system, equipped with hybrid technology, can be used both with diesel fuel and electric energy.

What is the purpose of the hybrid system?

It is often preferred in construction sites where there is no fixed transformer energy or where it is irregularly supplied.

The hybrid system is used to prevent malfunctions that may occur due to irregular electricity flow and fluctuations.

How does the hybrid system work?

The hybrid system, which gets its operating power from diesel fuel, can be easily disabled when desired. Thus, the machine can operate with grid energy in the construction site.

Optionally, the capacity of the hybrid system attached to our machines is determined according to the energy consumption needs of the facilities.

Automatic Lubrication System (Optional)

Perfect

Lubrication

Minimum

Oil Usage

Crusher Bearing

Lubrication

The Automatic Lubrication System is a system that is responsible for sending the required grease oil to the relevant parts during the use of the tracked crushing plant and when maintenance is needed.

It ensures flawless lubrication by evenly distributing grease oil to all components of the tracked crushing plant that require lubrication.

The automatic lubrication system provides great ease of maintenance by completing the lubrication process within seconds without requiring human labor, enabling the tracked crushing plant to be used in the most efficient manner.

During lubrication, it uses the optimal amount of oil and minimizes maintenance costs.

Hydraulic System

Hydraulic Control

Arms

Hydraulic

Belts

Hydraulic

Bunker Covers

The Hydraulic System enables the feeding bunker covers and stock bands to move without the need for manpower.

The system can be operated using hydraulic control arms and performs on-off operations in a short time.

What are the Adventages of Hydraulic System ?

- Works without the need for manpower

- Gives the related parts mobility in a short time.

- Fast and practical solution.

Contact us!

For Detailed Information About FTI-130 Mobile Crushing Plant

Contact us!

Contact Us

Let us know your preferred crushing and screening plant

Submit Your Request

Our sales consultants will contact you to discuss your request as soon as possible.

Get Called by Our Consultant

Detailed price offer, all information about your preferred crushing and screening plant will be shared with you by an Authorized dealer.

Get a Quote

Access our product catalog and get detailed information about our plants.