Vibrating Feeding Bunker

45 m³

Feeding Bunker

Vibro

Motor

Folding Type

Bunker Covers

Durable

Body Sheet

Vibrating Feeding Bunker is a system that gains the ability to vibrate with vibro motors and steel springs, and sends the products loaded into the bunker quickly towards the crusher thanks to its vibrating structure.

It has a long service life thanks to its durable body structure and A1 Quality steel springs, which are the biggest factor in vibration.

Wobbler Feeder

Wobbler

Feeder

Chain Gear

System

Sequential Disk

System

Automatic

Lubrication

Wobbler Feeder is designed to separate the products coming from the feeding hopper from dust, mud and dirt and to transfer clean product to the crusher.

The Wobbler Feeder, which separates dirty material with sequential discs moving forward and sends it to the bypass belt, prevents dirty material from entering the facility. This results in a clean final product.

The sequential discs derive their mobility from a chain gear system. This system is driven by a steel chain and has an automatic lubrication system.

Thanks to the automatic lubrication system, lubrication operations are completed practically and in a short time.

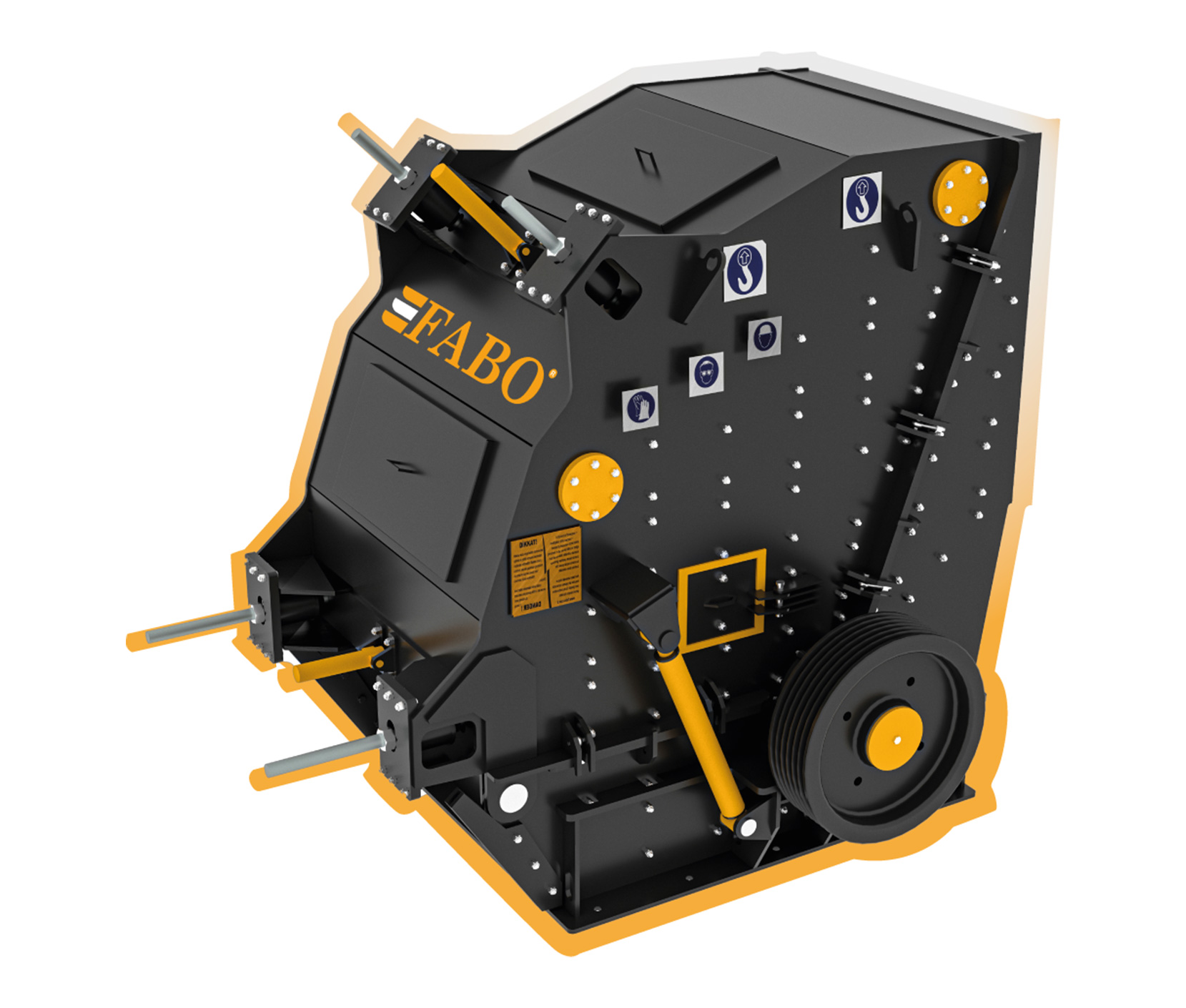

Turbo Impact Crusher

PDK-150

Impact Crusher

Durable

Pendulum System

Ø 1200x1500 mm

Rotor

Hydraulic

Body

Turbo Impact Crusher is designed to crush soft and medium hard stones.

The high-speed rotating rotor, mounted on paddles, crushes the products by forcing them against the pendulum. The hydraulically adjustable pendulum opening allows products to be cut to the desired size.

The crusher’s internal casing is protected by linings. These linings prevent wear on the primary impact crusher casing and ensure long service life. The protective linings, bolted to the crusher casing, can be easily replaced by a single operator.

Vibrating Bypass Screen

1600x5000 mm

Vibrating Screen

Screen

Weight

Durable

Screen Wire

Durable

Steel Spring

Bypass screens are activated when materials need to be diverted without passing through the crusher. Thanks to their double-deck design, they separate the material into two different size groups.

Positioned on the hopper before the crusher, the primary bypass grid sends the bypassed material directly to the stockpile if it matches the user’s desired size. This allows the first product to be obtained while ensuring that clean, mud-free, and dust-free material is fed into the plant. As a result, the quality of the final product is significantly improved.

Vertical Shaft Crusher Feeding Bunker

Crusher Top

Bunker

15 m³

Capacity

Vibro

Motor

Durable

Body Sheet

A 15 m³ capacity over-crusher hopper is positioned above the vertical shaft crusher. The over-crusher hopper is fed by stock conveyors. Its vibrating structure transfers the product to the vertical shaft crusher.

Vertical Shaft Crusher

Vertical Shaft

Crusher

Ø 1000 mm

Rotor

Easy

Maintenance

100 mm

Maximum Feed

Vertical Shaft Crusher is manufactured to turn medium hard production materials into sand and gravel.

The crushing process is carried out by throwing the stones in the crushing chamber to the lining by means of a rotor rotating at high speed. The protection linings inside the crusher protect the crusher body against wear and tear that may occur over time.

The protective liners are fixed to the crusher body with a bolt system. This allows them to be easily replaced by a single personnel.

Horizontal Vibrating Screen

2200x6000 mm

Vibrating Screen

Screen

Weight

Durable

Screen Wires

Durable

Steel Springs

The horizontal vibrating screen screens the crushed materials in the crusher and sends the products of the desired sizes to the stock area or crusher.

The vibrating screen, which has the ability to vibrate with durable steel springs, can operate uninterruptedly in the most difficult working conditions.

Thanks to the sieve wires that can be replaced in a short time, maintenance, repair and replacement operations are completed in a minimum time.

Stock and Return Belts

Conveyor

Belt

Belt

Traverses

Drive

Drums

Coupled

Motors

Stock conveyor belts are devices that quickly send the product to the crusher or stock area according to the size of the product after it has been sifted in the vibrating screen.

Control Cabinet and Electric Panel

PLC

Professional

Interface

Heat Sensor

Protection

Control Unit

It is the section where the stationary crushing and screening plant is operated and the movement of the stock bands is provided. All these operations are carried out in a cabin with the automation system developed by FABO Engineers.

Electric Panel

Electrical Panel is the system responsible for transmitting the electrical energy required for the operation of the Fixed Crushing and Screening Plant. Provides electricity distribution at different voltages to all equipment on the facility and ensures that all equipment operates at a voltage suitable for their specifications. There are different switches for each equipment on the electrical panel. In this way, in case of an emergency, the electrical current is terminated in the equipment that needs to be cut off.

Shipping Method

14-16

Trucks

Highway

Seaway

Railway

Stationary Crushing and Screening Plant is transported by 14-16 Trucks

Contact us!

For Detailed Information About Our Stationary Crushing Screening Plant

Contact Us!

Contact us

Let us know your preferred crushing and screening plant

Submit Your Request

Our sales consultants will contact you to discuss your request as soon as possible.

Get Called by Our Consultant

Detailed price offer, all information about your preferred crushing and screening plant will be shared with you by an Authorized dealer.

Get a Quote

Access our product catalog and get detailed information about our plants.

Reach Our Catalog

Ürün kataloğumuza erişin ve tesislerimiz hakkında detaylı bilgi edinin.

Kataloglarımıza Ulaşın

Detaylı fiyat teklifi, tercih ettiğiniz kırma eleme tesisi hakkındaki tüm bilgiler, bir Yetkili satıcı tarafından sizinle paylaşılacaktır.

Teklif Alın

Satış danışmanlarımız talebinizi en kısa sürede görüşmek üzere sizinle iletişime geçecektir.

Danışmanımız Tarafından Aranın

Tercih ettiğiniz kırma eleme tesisini bize bildirin