In today’s fast-moving construction industry, efficiency, sustainability, and cost-effectiveness are essential. A rubble crusher has become a key tool for meeting these demands. It helps manage demolition debris, process concrete waste, and prepare materials for reuse, making construction work faster, safer, and more resource-efficient. Rubble crushers play a vital role in modern projects by improving productivity, reducing costs, and supporting environmentally friendly practices.

What Is a Rubble Crusher and How Does It Work?

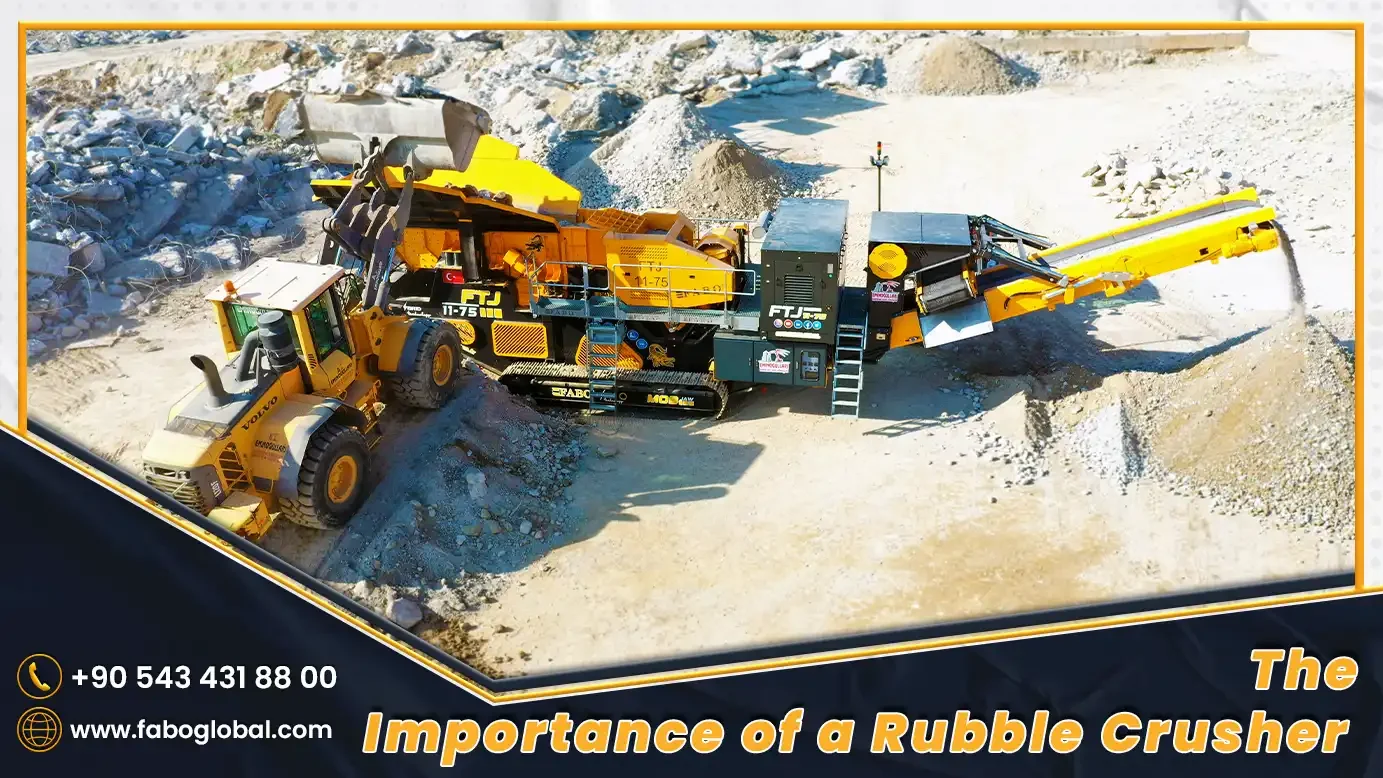

Simply put, a rubble crusher is a machine that breaks down construction debris into smaller, reusable pieces. You might also hear it referred to as a concrete crusher or debris crusher. These machines are designed to handle materials like concrete, bricks, asphalt, and natural stone.

So, how does it work? The rubble crusher applies mechanical force to crush large chunks of debris. Depending on the design, it can use jaws, impact plates, or rotary mechanisms to reduce material size. The result is a uniform aggregate ready for reuse in construction, eliminating the need for entirely new raw materials.

On top of recycling materials, rubble crushers also enhance safety on construction sites. Large, unstable debris can pose serious hazards, and a crusher efficiently removes these risks. Many modern machines come with conveyor systems and screening units, making the process smooth, safe, and efficient.

Core Features of Advanced Rubble Crushing Equipment

Not all rubble crushers are created equal. Modern equipment comes with features designed to maximize efficiency, reliability, and versatility:

- High Crushing Capacity: Handles large volumes of debris quickly to keep projects moving.

- Adjustable Output Sizes: Lets operators control the size of crushed material for different uses.

- Durable Build: Made with strong steel and wear-resistant components for tough construction environments.

- Integrated Screening: Separates materials effectively, reducing extra processing steps.

- Mobility: Mobile and track-mounted crushers can move easily between sites.

- Energy Efficiency: Designed to reduce energy use while maintaining high performance.

These features ensure rubble crushers are not just tools, but essential partners in modern construction projects.

Why Choose Fabo Global for Advanced Rubble Crushing Solutions?

- Proven Expertise: Years of experience designing crushing and screening solutions tailored to construction needs.

- Durable Equipment: Built for maximum performance and reliability in demanding environments.

- Innovative Technology: Incorporates energy-saving features and smart controls for optimized performance.

- Global Support: Access to service, spare parts, and technical support wherever you are.

Key Benefits of Using a Rubble Crusher in Construction Projects

The advantages of using a rubble crusher go far beyond just breaking down waste:

- Material Recycling: Turns demolition debris into usable aggregate for roads, landscaping, or concrete.

- Less Landfill Waste: Reduces the amount of debris sent to landfills, supporting greener practices.

- Improved Safety: Removes large, potentially dangerous rubble from the site.

- Space Savings: On-site crushing minimizes the need for storing debris.

- Time Efficiency: Provides ready-to-use materials quickly, keeping projects on schedule.

By integrating a rubble crusher, construction teams can increase productivity and promote environmentally responsible practices.

How Rubble Crushers Improve Efficiency on Construction Sites

Efficiency is the backbone of construction management, and rubble crushers make a noticeable difference:

- On-Site Processing: Crushing debris directly on-site eliminates time and costs associated with transport.

- Continuous Workflow: Mobile crushers maintain a steady flow of material, preventing downtime.

- Versatility: Capable of handling various debris types, including concrete slabs, asphalt, and natural stone.

- Integration: Works seamlessly with screening plants, conveyors, and loaders.

- Reduced Labor Needs: Automation and semi-automation decrease manual handling, saving time and costs.

In short, rubble crushers allow projects to move faster, safer, and more efficiently.

Common Challenges and Solutions with Rubble Crushers

While highly effective, rubble crushers can present challenges if not managed correctly:

- Blockages: Large debris can jam the machine. Pre-screening materials and regular maintenance prevent this.

- Wear and Tear: Hard materials can accelerate component wear. Using durable parts and scheduling inspections extends machine life.

- Dust: Crushing generates dust. Water sprays and dust suppression systems minimize exposure.

- Noise: Crushers can be loud. Enclosures, barriers, and strategic placement help reduce noise.

- Energy Use: High-capacity machines consume power. Modern, energy-efficient models and optimized operation schedules help control costs.

Addressing these issues ensures the rubble crusher continues to deliver maximum value.

How Rubble Crushers Save Costs in Construction Projects

Cost savings are one of the most compelling reasons to use rubble crushers:

- Reduced Material Expenses: Recycled debris can replace new aggregates.

- Lower Transport Costs: On-site processing removes the need to transport debris or raw materials.

- Labor Savings: Automation reduces the need for manual handling.

- Fewer Delays: Quick material processing keeps projects on schedule, preventing extra costs.

- Equipment Longevity: High-quality crushers last longer, minimizing maintenance and replacement costs.

Investing in a rubble crusher can directly improve a project’s bottom line.

Eco-Friendly Advantages of Crushing Construction Waste

Sustainability has become a priority in construction, and rubble crushers help projects meet environmental goals:

- Waste Reduction: Minimizes landfill contributions by recycling debris.

- Resource Conservation: Reduces the need for fresh aggregates.

- Lower Emissions: On-site processing decreases transport-related carbon emissions.

- Green Building Compliance: Supports LEED and other sustainability certifications.

- Circular Economy: Transforms waste into valuable resources for future construction.

By using rubble crushers, construction teams can significantly reduce their environmental footprint while maintaining efficiency.

Conclusion

Rubble crushers are much more than machines—they’re essential tools for efficient, cost-effective, and sustainable construction projects. From recycling debris to cutting costs and reducing environmental impact, rubble crushers transform the way construction teams operate. With Fabo Global’s advanced rubble crushing solutions, companies gain reliable, high-performing equipment that enhances productivity and supports sustainable practices.