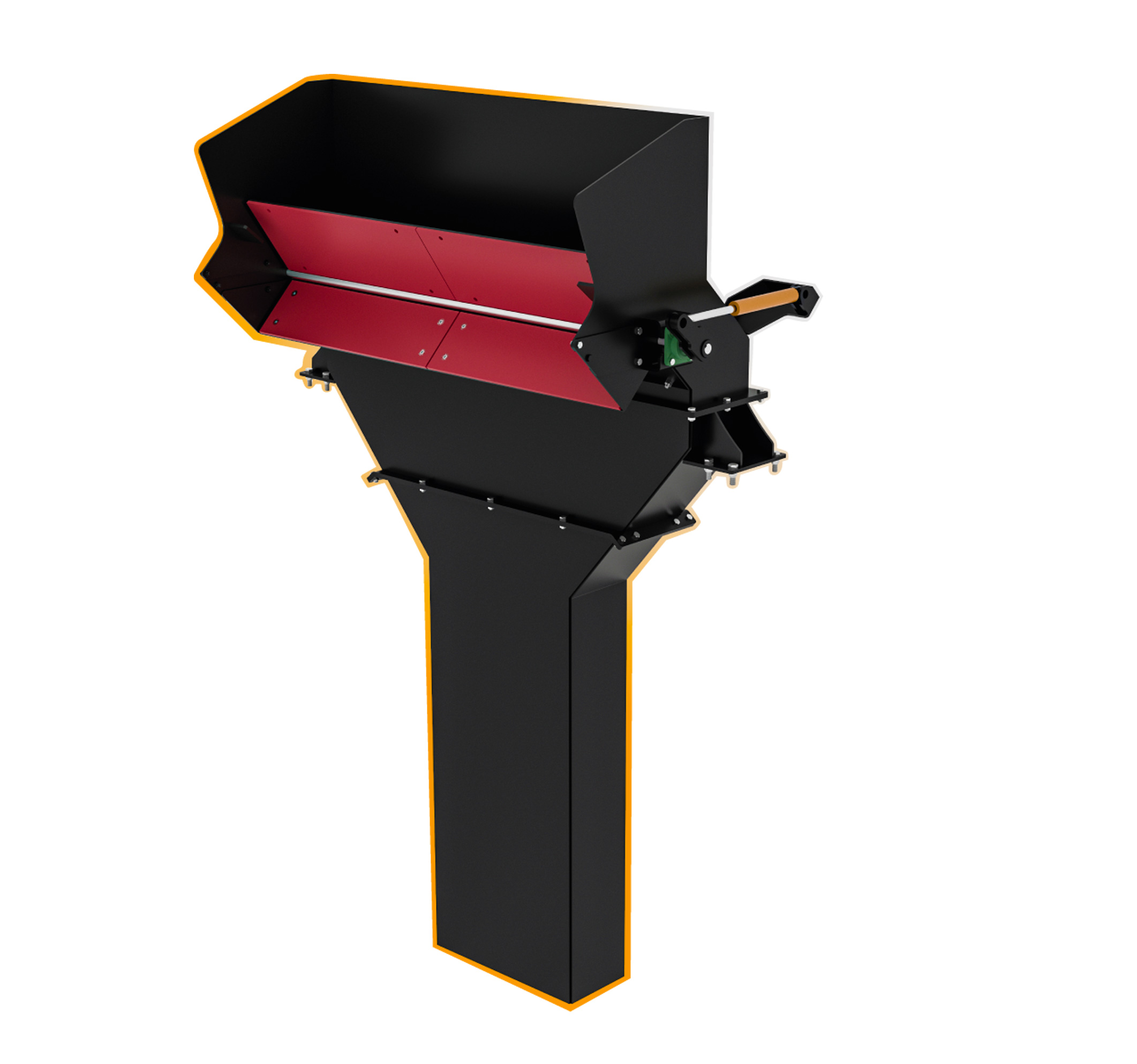

Vibrating Feeding Bunker

15 m³

Feeding Bunker

2x3 Kw

Vibro Motor

Folding Type

Bunker Covers

10 mm

Body Sheet

Vibrating Feeding Bunker is a system that gains the ability to vibrate with vibro motors and steel springs, and sends the products loaded into the bunker quickly towards the crusher thanks to its vibrating structure.

It has a long service life thanks to its durable body structure and A1 Quality steel springs, which are the biggest factor in vibration.

Wobbler Feeder (Optional)

Wobbler

Feeder

Chain Gear

System

Sequential Disk

System

Automatic

Lubrication

The Wobbler Feeder is designed to separate the products coming from the feeding hopper from dust, mud and dirt and to transfer clean products to the crusher.

The Wobbler Feeder, which separates the dirty material and sends it to the bypass band with the sequential discs moving in the forward direction, prevents the dirty material from entering the facility. In this way, a clean final product is obtained.

In-line discs get their mobility from the chain gear system. This system moves with a steel chain and has an automatic lubrication system.

Thanks to the automatic lubrication system, lubrication processes are completed in a practical and short time.

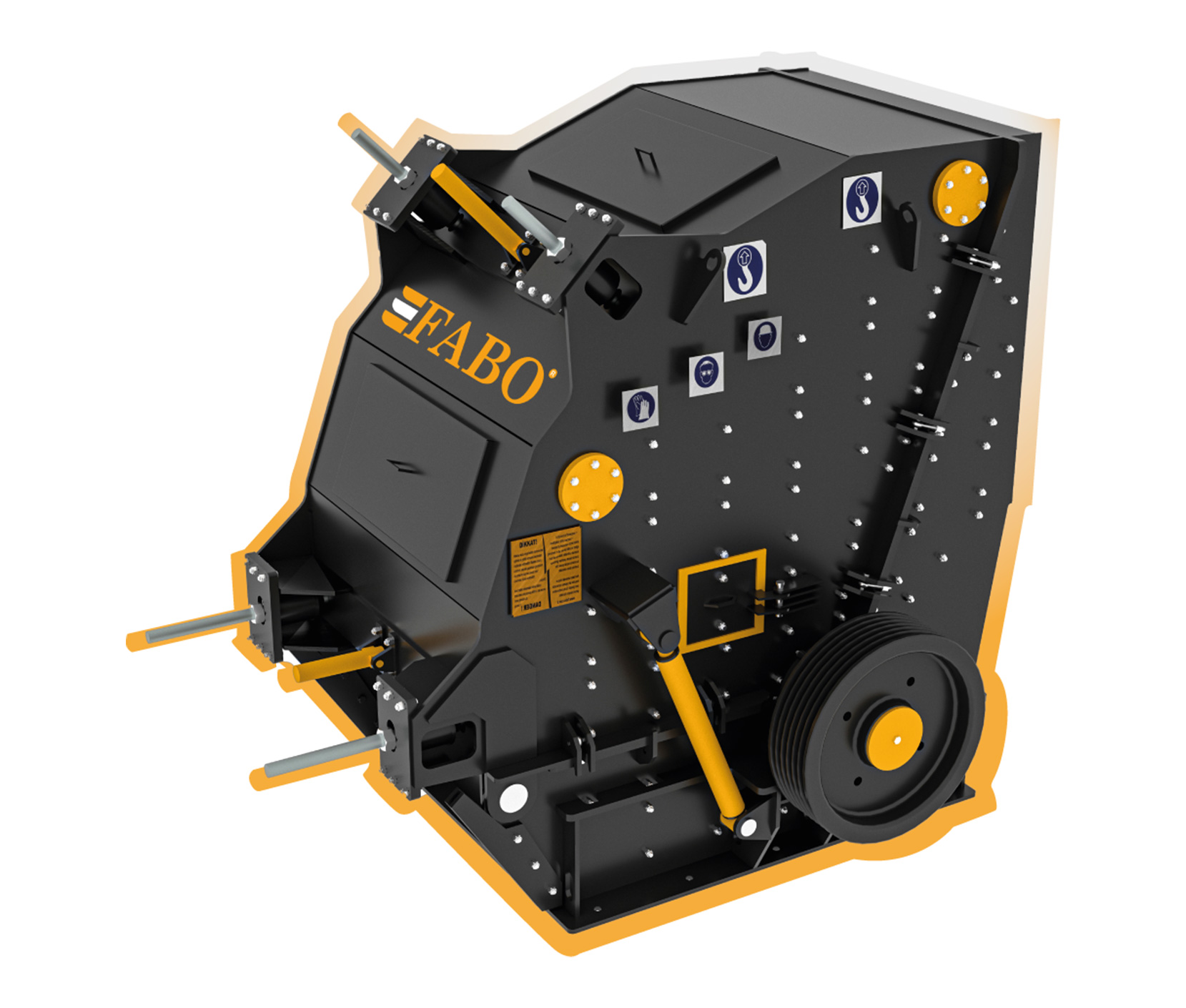

Turbo Impact Crusher

PDK-70

Impact Crusher

Durable

Pendulum System

Ø1100 x 700 mm

Rotor

Hydraulic

Body

Turbo Impact Crusher is designed to crush soft and medium hard stones.

The plant breaks the products by hitting the pendulum with the pallets on the rotor rotating at high speed. Thanks to the hydraulically adjustable pendulum opening, it enables the products to be obtained in the desired size.

The inner body of the crusher is protected by linings. Linings prevent wear of the turbo impact crusher body and offer a long service life. The protection linings, which are fixed to the breaker body with bolts, can be easily changed by a personnel.

Vibrating Screen

1300 x 3000 mm

Vibrating Screen

Screen

Weight

Durable

Screen Wires

Durable

Steel Springs

Vibrating Screen separates the products broken in the turbo impact crusher at the desired size and sends them to the stock area.

The size of screened product dimensions determined according to the customer’s request.

Vibrating sieve, which gains the ability to vibrate with durable steel springs, can work uninterruptedly under the toughest working conditions. Thanks to the sieve wires that can be changed in a short time, maintenance, repair and replacement processes are completed in a minimum time.

Flap System (Optional)

Flap

System

Hydraulic

Arm

Hydraulic

Piston

Flap Bottom

Groove

The flap system is a special system that allows the material broken in the crusher to be taken with the help of the front stock band before it is sent to the screen.

The plant disables the vibrating screen when it is desired to obtain a uniform product with the flap system.

The products are transferred to the flap system without being subjected to the screening process.

Flap system minimizes production time with its unique location just in front of the screen

Stock and Return Belts

Folding Type

Conveyor Belt

Belt

Traverses

Drive

Drums

Coupled

Motors

Folding type feeding and return belts are vehicles that quickly send the product to the crusher or the stock area according to the dimensions of the product after the relevant product is screened in the screen.

With its foldable structure, conveyor belts minimizes the dimensions of the machine it is on.

The band tires, which are produced resistant to wear, will never let you down and offer many years of service life.

Automation System

Professional

Interface

PLC

Remote

Connection

Heat Sensor

Protection (Opitional)

PRO-70 Mobile Crushing and Screening Plant is controlled by a full automation system. Thanks to the automation system panel on the machine, the way the machine works is adjusted.

Equipment that forms the basis of the facility such as crusher, vibrating screen, stock belts, feeding bunker are controlled by the automation system.

Crusher and vibrating screen bearings are temperature sensor controlled. In this way, all bearings are protected against unusual heating. The automation system that allows you to use the mobile crushing and screening plant in the most efficient way has been prepared with PLC and serves its users with the most advanced state of technology.

Automatic Lubrication System (Optional)

Perfect

Lubrication

Minimum

Oil Usage

Crusher Bearing

Lubrication

Screen Bearing

Lubrication

The Automatic Lubrication System is the system in charge of sending the grease that is reduced during the use of the crushing and screening plant and that needs maintenance to the relevant part.

The system distributes the grease evenly to all components of the mobile crusher that needs lubrication and provides perfect lubrication.

The automatic lubrication system, which provides ease of maintenance to a great extent, finishes the lubrication process in seconds without the need for manpower and allows the Mobile Crusher Plant to be used in the most efficient way.

The system uses the amount of oil in the most ideal way during lubrication and minimizes the maintenance cost.

Hydraulic System (Optional)

Hydraulic Control

Arms

Hydraulic

Belts

Hydraulic

Bunker Covers

Hydraulic

Flap

The Hydraulic System enables the feeding bunker covers and stock bands to move without the need for manpower.

The system can be operated using hydraulic control arms and performs on-off operations in a short time.

What are the Adventages of Hydraulic System ?

- Works without the need for manpower

- Gives the related parts mobility in a short time.

- Fast and practical solution.

Mobile Chassis

IPE 400

Mobile Chassis

2"

King Pin

Hydraulic

Feet

Brake

Axle System

The Mobile Chassis 400 is the system that contains all the equipment in the facility, which is made of IPE material. The chassis, which has a braked axle system, is moved on 2 axles and 4 wheels.

There is a 2” king pin on the mobile chassis, which can be transported by a truck. With its hydraulic feet, the plant can easily come to the transport position.

Contact us!

For Detailed Information About PRO-70 Mobile Crushing and Screening Plant

Contact us!

Contact Us

Let us know your preferred crushing and screening plant

Submit Your Request

Our sales consultants will contact you to discuss your request as soon as possible.

Get Called by Our Consultant

Detailed price offer, all information about your preferred crushing and screening plant will be shared with you by an Authorized dealer.

Get a Quote

Access our product catalog and get detailed information about our plants.

Reach Our Catalog

Ürün kataloğumuza erişin ve tesislerimiz hakkında detaylı bilgi edinin.

Kataloglarımıza Ulaşın

Detaylı fiyat teklifi, tercih ettiğiniz kırma eleme tesisi hakkındaki tüm bilgiler, bir Yetkili satıcı tarafından sizinle paylaşılacaktır.

Teklif Alın

Satış danışmanlarımız talebinizi en kısa sürede görüşmek üzere sizinle iletişime geçecektir.

Danışmanımız Tarafından Aranın

Tercih ettiğiniz kırma eleme tesisini bize bildirin