PRO Series

Portable Crushing Screening Plants

PRO Series Mobile Crushing and Screening Plants are produced to crush and screen soft and medium hard production materials. The plant has a production capacity of 70 T/H and 450 T/H in different models.

MCK Series

Portable Hard Stone Crushing Screening Plants

MCK Series Mobile Hard Stone Crushing and Screening Plants are manufactured to crush and screen high hardness production materials. It is produced as a single or double chassis in different models. It contains multiple crushers.

MCK series has a production capacity of 60 T/H – 300 T/H in different models.

FULLSTAR Series

Portable Crushing Screening Washing Plant

FULLSTAR Series Mobile Crushing and Screening Washing Plants are produced to perform crushing and screening of high hardness production materials.

Thanks to its vibrating washing screen and spiral washer, it provides a clean final product that is free from dirt.

It is produced as a single or double chassis in different models and contains more than one crusher.

It has a production capacity of 60 T/h – 300 T/h in different models.

MCC Series

Portable Cone Crushers

The MCC Series Mobile Cone Crushers are designed to turn hard stones into gravel.

Thanks to its cone crusher technology, it offers the possibility of obtaining the desired final product size. 4 different final products can be obtained on a single chassis.

Different models have production capacities ranging from 80 T/H to 340 T/H.

MVSI Series

Portable Vertical Shaft Impact Crushers

The MVSI Series Mobile Vertical Shaft Impact Crushers are designed to turn hard and soft production materials into sand and gravel.

Our MVSI model, which has the ability to produce a high amount of 0-5 mm sand, can obtain 4 different final product sizes simultaneously.

Different models have production capacities ranging from 100 T/H to 400 T/H.

MDMK Series

Portable Secondary Impact Crushers

The MDMK Series Mobile Secondary Impact Crushers are designed to perform crushing and screening of hard and soft production materials.

This model, which takes its crushing power from the DMK series secondary impact crusher, is controlled by an automation system operated by a single person.

Different models have production capacities ranging from 130 T/H to 350 T/H.

MJC Series

Portable Jaw Crusher with Screen Plants

The MJC Series Mobile Hard Stone Crushing and Screening Plants are designed to perform crushing and screening of high hardness production materials.

It takes its crushing power from the CLK series jaw crusher.

Different models have production capacities ranging from 60 T/H to 320 T/H.

MTK Series

Portable Tertiary Crushers

The MTK Series Mobile Tertiary Crushers are designed to turn hard and soft production materials into sand and gravel.

Different models have production capacities ranging from 60 T/H to 300 T/H.

ME - MEY Series

Portable Screening and Washing Plants

The MEY Series Mobile Screening and Washing Plants are designed to perform screening and washing of production materials.

Thanks to its washing system, it provides obtaining clean final products free of dirt. The washing processes of the products are performed with vibrating washing screen and spiral washer.

Different models have production capacities ranging from 70 T/H to 300 T/H.

MJK- MIC Series

Portable Primary Jaw and Impact Crusher

The MJK-MIC Series Mobile Crushing Plants are plants with a primary crusher located on a mobile chassis.

The MJK Series is produced systematically with a Feeding Hopper, Grizzly Feeder, Bypass Conveyor, Jaw Crusher, and Stock Conveyor.

The MIC Series is produced systematically with a Feeding Hopper, Grizzly Feeder, Bypass Conveyor, Turbo Impact Crusher, and Stock Conveyor.

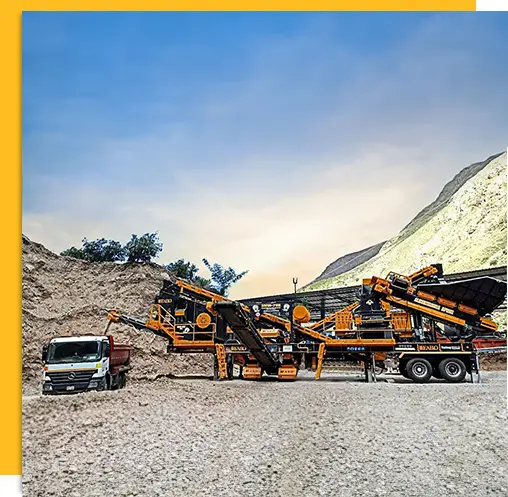

Portable Crushing and Screening Plants for Efficient Aggregate Production

Fabo Global’s portable crushing and screening plants are designed to process aggregates quickly and efficiently right on-site. With high-capacity crushers, integrated screens, and conveyors on a single mobile platform, these plants streamline material flow and reduce transportation costs. Whether producing fine sand or coarse aggregates, operators can achieve precise sizing while maximizing daily productivity.

High-Performance Portable Crushers and Screeners for Mining & Construction

Our portable crushing and screening systems deliver reliable performance for mining and construction projects. Heavy-duty crushers and multi-deck screens handle a wide range of materials, including hard rock, gravel, and recycled concrete. Fast setup and mobility ensure continuous production while reducing transportation and operational costs.

Cost Efficiency and ROI of Portable Crushing and Screening Plants

Investing in a portable crushing plant provides long-term financial benefits. On-site processing reduces hauling and handling expenses, while high-efficiency screening maximizes material recovery and product quality. Over time, these plants increase operational efficiency, lower fuel and labor costs, and deliver a strong return on investment by boosting daily output and minimizing downtime.

Reliable Portable Crushing Screening Plants for Mining, Quarrying, and Recycling

Fabo Global’s portable plants are built for versatility and durability. They process ore, aggregates, concrete, asphalt, and demolition debris efficiently. Rugged construction, wear-resistant components, and advanced automation ensure dependable operation even in demanding environments, helping keep projects on schedule and within budget.

Key Advantages of Portable Crushing Screening Plants

Portable crushing plants offer unmatched flexibility and efficiency. They can be relocated quickly, require minimal site preparation, and adapt to different materials and production goals. Additional benefits include reduced operating costs, improved fuel efficiency, high-quality output, and integration with automated control systems, making them ideal for operators seeking both productivity and versatility.

Why Fabo Global is the Trusted Choice for Portable Crushing Plants?

Fabo Global is recognized worldwide for engineering durable, high-performance portable crushing and screening solutions. Every plant is designed with precision, tested for reliability, and supported by global service options. Operators trust Fabo Global for innovative designs, robust construction, and reliable performance that maximizes productivity and ensures projects are completed on time and on budget.

Our portable crushing and screening plants are engineered to deliver reliable performance.

Contact us to achieve superior production results in challenging construction environments, process even the toughest materials with FABO Global’s advanced crushing and screening technologies, and experience the proven quality of FABO Global.

Click below to watch our presentation videos.

FAQ - Portable Crushing Screening Plant

1. What is a portable crushing screening plant?

2. How does a portable crushing screening plant work?

3. What types of materials can it process?

4. What makes a portable plant better than a stationary one?

- Mobility: You can easily move it from one site to another.

- Cost savings: On-site processing reduces hauling and handling costs.

- Flexibility: Adaptable to different materials and production requirements.

- Quick setup: Minimal installation time means you can start production fast.

5. How should I maintain a portable crushing screening plant?

- Regularly inspect belts, screens, and moving parts.

- Lubricate bearings and hydraulic components.

- Clean dust, debris, and material buildup.

- Monitor electrical and automation systems.

- Follow the preventive maintenance schedule recommended by the manufacturer.

Regular care keeps the plant running efficiently and extends its service life.

9. Do I need permits to operate one?

6. Can it handle recycled materials?

7. What should I consider when choosing a portable crushing screening plant?

- The type and hardness of the material you’ll process.

- Your required production capacity.

- Desired product size and screening accuracy.

- Mobility and setup time.

- Maintenance and operating costs.

Choosing the right configuration ensures smooth operation, maximum efficiency, and minimal downtime.