Producing reliable, high-quality sand is a critical part of building strong and durable structures. Yet, raw sand rarely arrives in perfect condition. It often contains clay, dust, silt and other impurities that can affect performance, consistency and long-term strength. This is where an efficient Sand Washing Plant plays a vital role. Sand washing systems play a crucial role in transforming raw material into cleaner, stronger and more reliable sand, supporting both performance and operational stability. Understanding how these systems work, why they matter and how advanced engineering technology enhances quality and efficiency highlights the importance of choosing powerful, precision-designed solutions such as those developed by Fabo Global.

What Is a Sand Washing Plant and How Does It Work?

A Sand Washing Plant is a smart and highly functional system designed to clean, separate, and refine sand before it is used in real projects. Raw sand rarely comes in perfect condition. It often contains clay, silt, mud, dust, stones, and other unwanted materials that can weaken performance. That’s exactly where a modern sand washing system steps in.

Here’s how it works in simple terms. First, raw material is fed into the washing unit. Inside, powerful washing mechanisms and pressurized water loosen and remove impurities. Screening units separate oversized particles while keeping the right grain sizes. Advanced systems like hydrocyclones recover valuable fine material that would otherwise be lost. Finally, dewatering systems remove excess moisture, leaving behind clean, high-quality sand that is easy to store, transport, and use. In short, a Sand Washing Plant turns raw, inconsistent sand into a reliable material that industries can confidently depend on.

Why Is It Essential for Quality Sand Production?

High-quality sand is not a luxury—it is a requirement for safe, durable, and long-lasting structures. When sand is not properly washed, it carries dust and clay that weaken strength. This can lead to poor bonding, cracks, structural failures, and costly repairs.

A reliable sand washing solution ensures:

- Stronger bonding in concrete and mortar

- Higher durability and resistance

- Reduced cracking and structural risk

- Reliable performance for industrial applications

Simply put, when the sand is clean, everything built with it performs better. That is why using a Sand Washing Plant is no longer optional for professional production—it has become essential.

Key Benefits of Using an Efficient Sand Washing Plant for Construction

Using an efficient Sand Washing Plant provides significant advantages for construction companies and industrial producers. It doesn’t just clean sand; it supports the entire production process.

Some of the most important benefits include:

- Consistent Quality: Stable particle sizes and uniform sand gradation

- Less Waste: Reduced rejection of material

- Lower Maintenance: Cleaner materials protect mixers and batching systems

- Better Efficiency: Faster production without constant quality concerns

- Standards Compliance: Supports material quality requirements

For construction professionals, this means smoother operations, stronger results, and better reliability from start to finish.

Common Sand Quality Problems and How a Sand Washing Plant Solves Them

Unwashed sand brings several hidden problems. Clay and dust weaken bonding. Excess fine particles increase water demand. Organic materials can affect curing. Oversized grains disrupt consistency. All of these issues lead to weaker performance and wasted resources.

A Sand Washing Plant solves these problems by:

- Removing dust, clay, and unwanted fines

- Separating the right grain sizes

- Eliminating organic materials

- Improving moisture balance

- Delivering more consistent, ready-to-use material

As a result, industries experience fewer failures, more predictable outcomes, and stronger structural reliability.

How an Efficient Sand Washing Plant Improves Product Quality and Output

An efficient Sand Washing Plant does more than clean sand—it helps operations work smarter and more productively. Advanced washing systems ensure a precise material structure, while screening technology guarantees the right particle sizes. Fine material recovery reduces waste, and intelligent water recycling helps control costs.

This leads to:

- Consistent material performance

- Increased usable material output

- Faster production cycles

- Reduced interruptions

- Better control over moisture and quality

The final outcome is simple: cleaner sand, smoother production, higher productivity, and dependable long-term performance.

Which Sand Washing Plant System Is Best for Your Operation?

Not every operation has the same needs. The best Sand Washing Plant depends on material characteristics, production targets, working conditions, and processing goals. Different washing technologies are designed for different tasks.

Common system options include:

- Screw Washers: Strong and reliable for coarse material

- Bucket Wheel Washers: Efficient cleaning with controlled water use

- Hydrocyclone Systems: Perfect for fine material recovery and accurate separation

- Mobile Sand Washing Plants: Flexible and easy to relocate when needed

- Complete Washing and Screening Solutions: Ideal for high-capacity professional operations

The right choice is the one that supports your production goals, maintains high quality, and keeps your operation efficient and sustainable.

Sand Washing Plant Applications in Mining, Construction and Concrete Production

A Sand Washing Plant is widely used because of how versatile and valuable it is across multiple industries.

Mining

In mining environments, washed sand supports material stability and improves processing quality. Clean sand ensures reliable downstream performance and better grading.

Construction

Construction depends heavily on sand that is consistent, strong, and clean. From foundations to finishing, washed material contributes to safer and more durable results.

Concrete Production

Concrete plants rely on precision. Clean, stable sand improves mix strength, reduces cracking, and enhances the final finish. A dependable washing system helps deliver consistent production every day.

Across all industries, an efficient washing solution means better quality, fewer risks, and greater confidence.

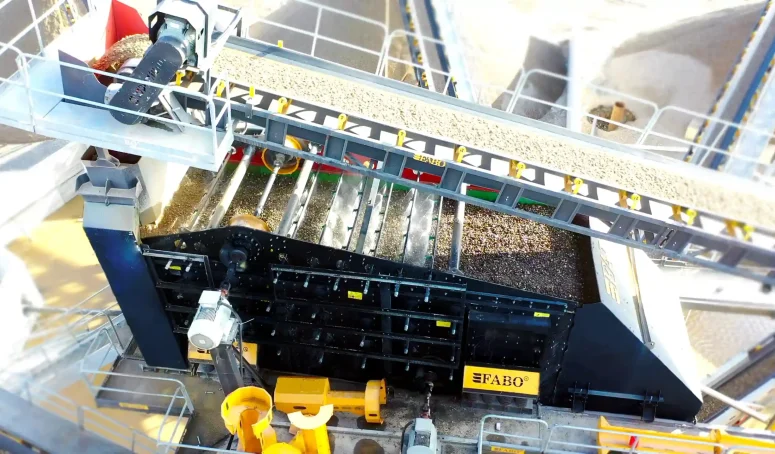

High-Performance Sand Washing Plant Engineered by Fabo Global

Fabo Global designs high-performance Sand Washing Plant solutions built for demanding industrial environments. Each system is engineered with strength, efficiency, and long-term reliability in mind.

What makes Fabo Global solutions stand out?

- Durable, long-lasting construction

- Advanced washing and screening technology

- Excellent fine material recovery

- Smart water management and recycling

- Reduced operating costs

- Flexible configurations for different applications

With engineering expertise and experience in crushing, screening, and concrete plant systems, Fabo Global provides trusted sand washing solutions that support professional production requirements. These systems help industries achieve cleaner material, higher efficiency, and dependable performance every day.