If you work in construction, infrastructure, or heavy-duty project environments, you already know that proper ground preparation determines the overall success of any project. Whether it is a highway, a commercial construction site, or an airport runway, everything starts with a solid, well-compacted fill layer. This is exactly why Stabilized Fill Material Crushers have become one of the most essential pieces of equipment on modern job sites.

What Is a Stabilized Fill Material Crusher and How Does It Work?

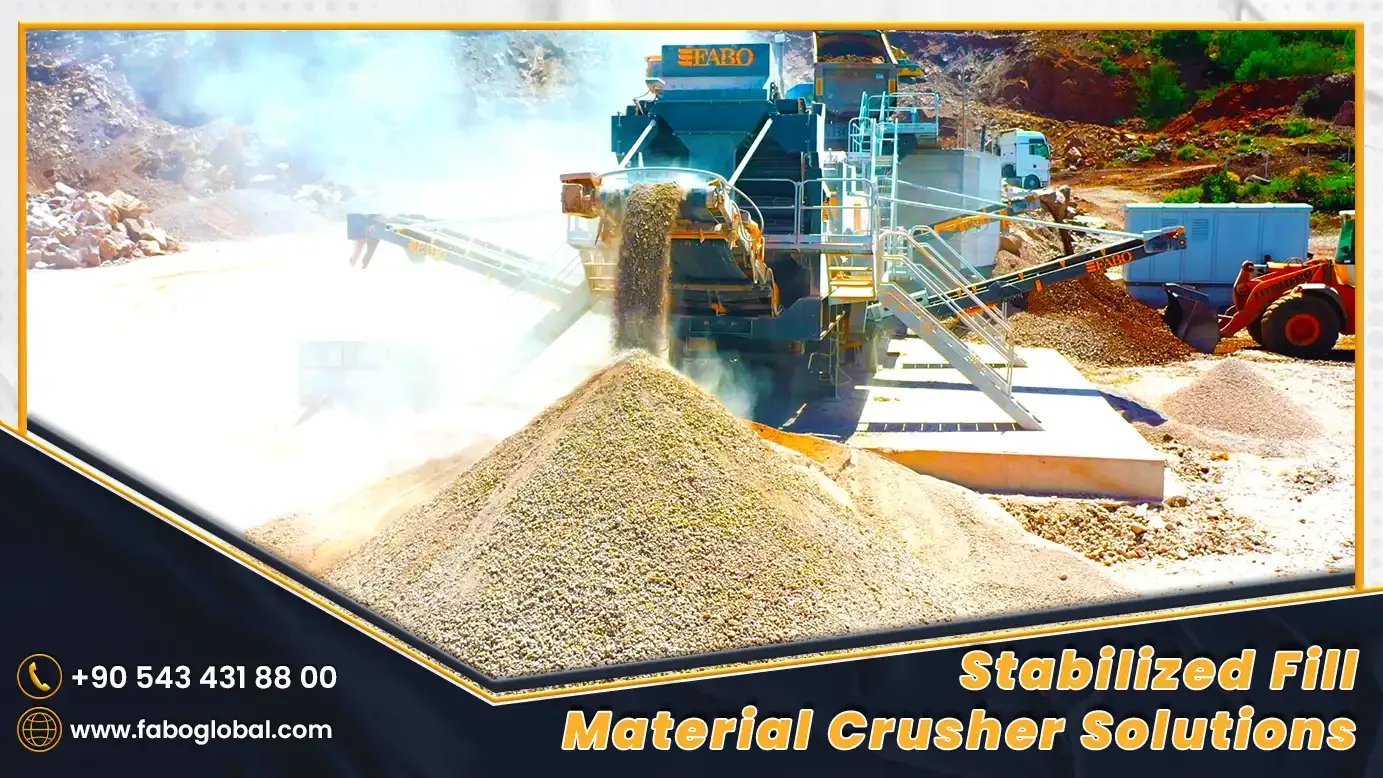

A Stabilized Fill Material Crusher is a specialized crushing and screening system designed to convert natural aggregates, soil blends, or recycled concrete and asphalt into durable, compactable stabilized fill. This equipment plays a critical role in producing base layers capable of supporting the loads of roads, buildings, and heavy structures.

Its general working principle includes:

- Primary crushing: Reducing large rock or concrete pieces into smaller sizes

- Secondary and tertiary crushing: Refining the material until it meets the required gradation for stabilization

- Screening: Separating material according to specific sieve sizes

As a result, the system produces high-quality, homogeneous stabilized fill material capable of carrying long-term loads even under demanding site conditions. Achieving this level of performance is only possible with properly calibrated, reliable, and precisely engineered crusher equipment.

Primary Types of Stabilized Filler Materials

Based on soil characteristics and project requirements, various stabilized fill types are produced. The most widely used types in English-speaking countries include:

Cement-Stabilized Material

Aggregates are mixed with a controlled amount of cement to achieve high-strength fill capable of supporting heavy loads.

Lime-Stabilized Soil

Used especially in clay-rich or problematic soils; lime reduces plasticity and increases compactability. It is preferred in areas with weak natural ground.

Fly Ash Stabilized Fill

Fly ash improves workability and enhances long-term durability. It is considered an eco-friendly stabilization method.

Mechanically Stabilized Aggregate

Produced without binders, using precise gradation control. It is a cost-effective and efficient fill type.

Recycled Stabilized Fill

Created by crushing old concrete or asphalt. It reduces costs and minimizes waste. As sustainability requirements increase, this method is becoming more popular.

The performance of these materials depends heavily on consistent grain distribution—something only achievable with a high-quality Stabilized Fill Material Crusher.

Key Benefits of Stabilized Fill Material Crusher

Cement-Stabilized Material

Aggregates are mixed with a controlled amount of cement to achieve high-strength fill capable of supporting heavy loads.

Lime-Stabilized Soil

Used especially in clay-rich or problematic soils; lime reduces plasticity and increases compactability. It is preferred in areas with weak natural ground.

Fly Ash Stabilized Fill

Fly ash improves workability and enhances long-term durability. It is considered an eco-friendly stabilization method.

Mechanically Stabilized Aggregate

Produced without binders, using precise gradation control. It is a cost-effective and efficient fill type.

Recycled Stabilized Fill

Created by crushing old concrete or asphalt. It reduces costs and minimizes waste. As sustainability requirements increase, this method is becoming more popular.

The performance of these materials depends heavily on consistent grain distribution—something only achievable with a high-quality Stabilized Fill Material Crusher.

Stabilized Fill Material Crusher Costs and Return on Investment (ROI)

Purchasing a Stabilized Fill Material Crusher is a major investment, but most companies recover the cost quickly. Pricing depends on production capacity, crusher type, mobility (mobile or stationary), additional screening/mixing units, and automation level.

Although the initial investment may appear high, producing stabilized fill directly on-site provides major savings:

- Significant reduction in transportation costs

- Eliminating the need to purchase expensive aggregates

- Preventing supply delays

- Producing material precisely in the required amount, minimizing waste

For these reasons, most companies achieve full ROI within 6–24 months, with large contractors often recovering the investment even faster.

Types of Crushers Suitable for Stabilized Fill Material Production

Not all crushers deliver the same performance. Choosing the right machine is essential for achieving the ideal gradation and material strength.

Jaw Crushers

Ideal for primary crushing of hard and large-volume materials.

Cone Crushers

Excellent for producing high-quality, well-shaped aggregates.

Impact Crushers

Suitable for medium-hard materials and recycling applications.

Vertical Shaft Impact (VSI) Crushers

The best option for producing fine, homogeneous aggregates required for stabilization.

Mobile Crushers

Provide flexibility, fast setup, and the ability to produce material directly on-site.

The correct crusher combination is selected based on project goals, material type, and required production capacity.

Advanced Technologies in Fabo Global’s Stabilized Fill Material Crushers

Fabo Global is known worldwide for its high-efficiency, durable, and technologically advanced crushing and screening systems. Key technologies featured in its stabilized fill production solutions include:

Smart Automation Systems

Real-time monitoring automatically optimizes machine settings.

Energy-Efficient Motors

Reduce energy consumption and lower operating costs.

Modular Screening and Mixing Units

Allow easy configuration for different stabilized fill types.

Durable Components and Wear Parts

Provide longer machine life and reduced maintenance requirements.

Mobile, Stationary, and Semi-Mobile Options

Offer suitable solutions for contractors and projects of all sizes.

With these technologies, companies can produce stabilized fill faster, more efficiently, and with higher quality—ultimately increasing their competitive advantage.