FTJ Series

Mobile Jaw Crusher

The FTJ Series Mobile Jaw Crusher is produced with a feeding bunker, generator, jaw crusher, separator belt and stock belts. It can be moved on steel tracks using a remote control and successfully completes all commands given by the user in challenging climate conditions and rough terrain.

FTI Series

Mobile Impact Crusher

The Mobile Turbo Impact Crushing and Screening Plant is produced with a feeding bunker, generator, turbo impact crusher, vibrating screen, separator conveyor, and stock conveyor. The FTI Series Mobile Turbo Impact Crushing and Screening Plant, which is moved on steel tracks with remote control, successfully completes all commands given by the user in all challenging weather conditions and rough terrains.

FTC Series

Mobile Cone Crusher

The Mobile Cone Crusher Plant is produced with a feeding bunker, generator, cone crusher, vibrating screen, separator belt, and stock belt. The FTC Series Tracked Mobile Cone Crusher Plant, which is moved on steel tracks with remote control, successfully completes all commands given by the user in all challenging climate conditions and on rough terrain.

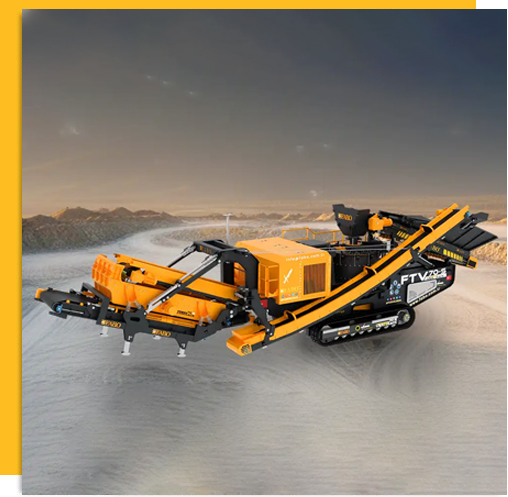

FTV Series

Mobile Vertical Shaft Impact Crusher

Mobile Vertical Shaft Impact Crushing and Screening Plant is produced with a feeding bunker, generator, vertical shaft impact crusher, vibrating screen, separator conveyor and stock conveyor. FTV Series Mobile Vertical Shaft Impact Crushing and Screening Plant, which is moved on steel tracks with remote control, successfully completes all the commands given by the user on rough climate conditions and on rugged terrain.

FTT Series

Mobile Tertiary Crusher

FTT Series Mobile Tertiary Crushing and Screening Plant features a compact structure consisting of a feeding bunker, generator, tertiary crusher, vibrating screen, separator belt, and stock conveyor. Equipped with a crawler track system, this mobile plant can be easily controlled via remote control. The FTT Series delivers high performance even under harsh climate conditions and on rugged terrains, reliably and effectively executing all commands from the operator.

Mobile Crusher Plants Engineered for Efficiency

FABO Global’s mobile crusher plants are built to keep your production moving with less effort and lower costs. Every unit is designed to deliver strong performance while using energy and fuel more efficiently. Whether you’re processing hard rock or recycled materials, the plant maintains steady output with fewer slowdowns. This means faster work cycles, cleaner operations, and less time spent on maintenance—helping your team get more done every day.

Mobile Crushing and Screening Plant for Mining, Quarrying, and Recycling Projects

A Mobile Crushing Screening Plant gives operators the flexibility they need across different sectors. In mining, it brings the crushing process directly to the excavation area. In quarrying, it keeps aggregate production running without the need for fixed installations. And in recycling, it quickly turns concrete, asphalt, or demolition waste into usable material. Its mobility, fast setup, and easy relocation make it an ideal choice for companies that manage dynamic, fast-paced project sites.

Cut Costs and Increase Output with Mobile Screening and Crushing Plant

Using a mobile crusher plant allows you to reduce transportation and material-handling costs right from the start. Instead of moving material long distances, the crushing happens directly at the source. This saves fuel, reduces equipment wear, and speeds up the entire production cycle. At the same time, high-performance crushers and accurate screening units maximize output, helping you deliver consistent, high-quality products while keeping operating expenses under control.

Advanced Mobile Screening and Crushing Solutions for Aggregate Producers

Aggregate producers need equipment they can rely on every day. FABO Global’s mobile solutions feature multi-deck screens, adjustable crusher settings, and intelligent controls that help you achieve precise material specifications. Whether you’re producing road base, asphalt aggregates, or fine sand, the system is designed to deliver clean, consistent results even during long production shifts. It’s the performance you need to meet tight deadlines and demanding client expectations.

Mobile Crushing and Screening Plants Built for Durability in Demanding Environments

Harsh climates, abrasive materials, and continuous operation—our equipment is built to handle it all. FABO Global mobile crusher plants use reinforced frames, wear-resistant components, and robust engineering to ensure long-term reliability. From hot quarry sites to cold mining environments, each Mobile Crushing Screening Plant maintains stable performance and minimizes unexpected downtime, giving you the durability your field operations depend on.

Advantages of Mobile Screening and Crushing Plant

A mobile crusher plant offers major advantages for operators who need flexibility and speed. It installs quickly, moves easily between job sites, and adjusts to different material needs with minimal effort. You spend less on transportation, require fewer fixed structures, and gain the ability to shift production whenever your project changes. With improved fuel efficiency, automation, and integrated screening options, it simplifies your workflow while improving product quality.

Why Choose FABO Global for Mobile Screening and Crushing Plant

FABO Global stands out for delivering reliable, high-performance mobile crusher plants backed by years of industry expertise. Every Mobile Crushing Screening Plant we manufacture combines advanced technology with durable components and careful quality control. We support customers with tailored configurations, responsive after-sales service, fast spare-part solutions, and worldwide delivery. Working with FABO Global means gaining a partner committed to helping you increase productivity and reduce operational challenges.

Tracked Mobile Plants

Mobile Crushing Screening Plant are mobile plants that move on pallets and can be transported more easily. Tracked mobile plants are often used on construction sites or road construction projects. These facilities are designed to crush stone, sand, gravel and other natural materials into desired sizes. Mobile crushers can also be used to process recyclable materials. Tracked mobile plants are very popular due to their mobility. They can be moved from one place to another without needing a special vehicle to transport materials at work. In this way, it saves time and cost.

Our tracked mobile crusher plants are as follows.

Mobile Jaw Crusher | Mobile Impact Crusher | Mobile Cone Crusher | Mobile Vertical Shaft Impact Crusher

Contact us to produce with the best mobile crusher plant in difficult construction sites, to process the hardest stones with the FABO Global crushing and screening plant and to meet FABO Global quality.

Click to watch our presentation videos.

FAQ - Mobile Crushing Screening Plant

1. What is a mobile crushing plant?

2. What does a crusher plant do?

3. What are the types of crushers?

In mobile crushing plants, the most commonly used crusher types include:

-

Jaw Crushers: Ideal for primary crushing of hard rocks and ores.

-

Impact Crushers: Designed to produce smaller, more uniform aggregates.

-

Cone Crushers: Used for secondary or tertiary crushing, efficiently processing medium to hard materials.

-

Mobile Tertiary Crushers: Specialized for fine crushing and producing high-quality aggregates.

-

Mobile Vertical Shaft Impact (VSI) Crushers: Suitable for shaping and producing precisely graded materials.

Each type of crusher should be selected based on the material type and the specific requirements of the project.

4. Which is better: mobile crusher or stationary crusher?

5. What are the difficulties of crushers and how to solve them?

6. How to maintain a mobile crusher?

- Regular inspection of belts, screens, and crusher parts

- Lubricating moving components as recommended

- Cleaning dust and debris to prevent clogging

- Checking hydraulic systems and electrical components

- Scheduling periodic preventive maintenance

Proper maintenance ensures longer lifespan, higher performance, and reduced downtime.

7. What is the cost of a crusher plant?

8. What are the requirements for a crusher plant?

- Adequate space for safe operation and material handling

- Access to power supply or fuel

- A trained operator

- Compliance with local safety, environmental, and operational regulations

- Regular maintenance schedules

Meeting these requirements ensures safe and efficient crushing operations.